48-531 Fabricating Customization: Prototype

Professor Jeremy Ficca

ETFE Envelope Design

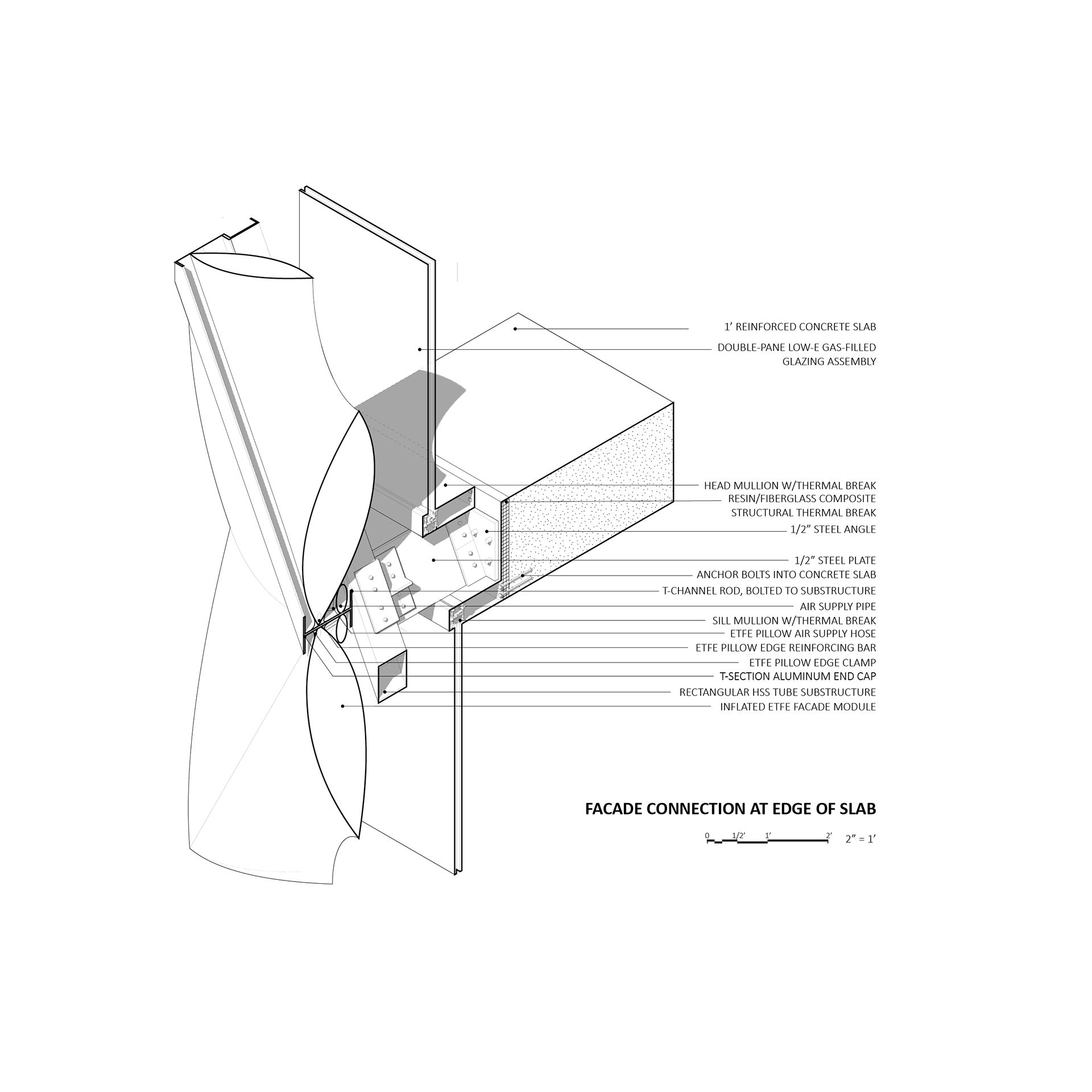

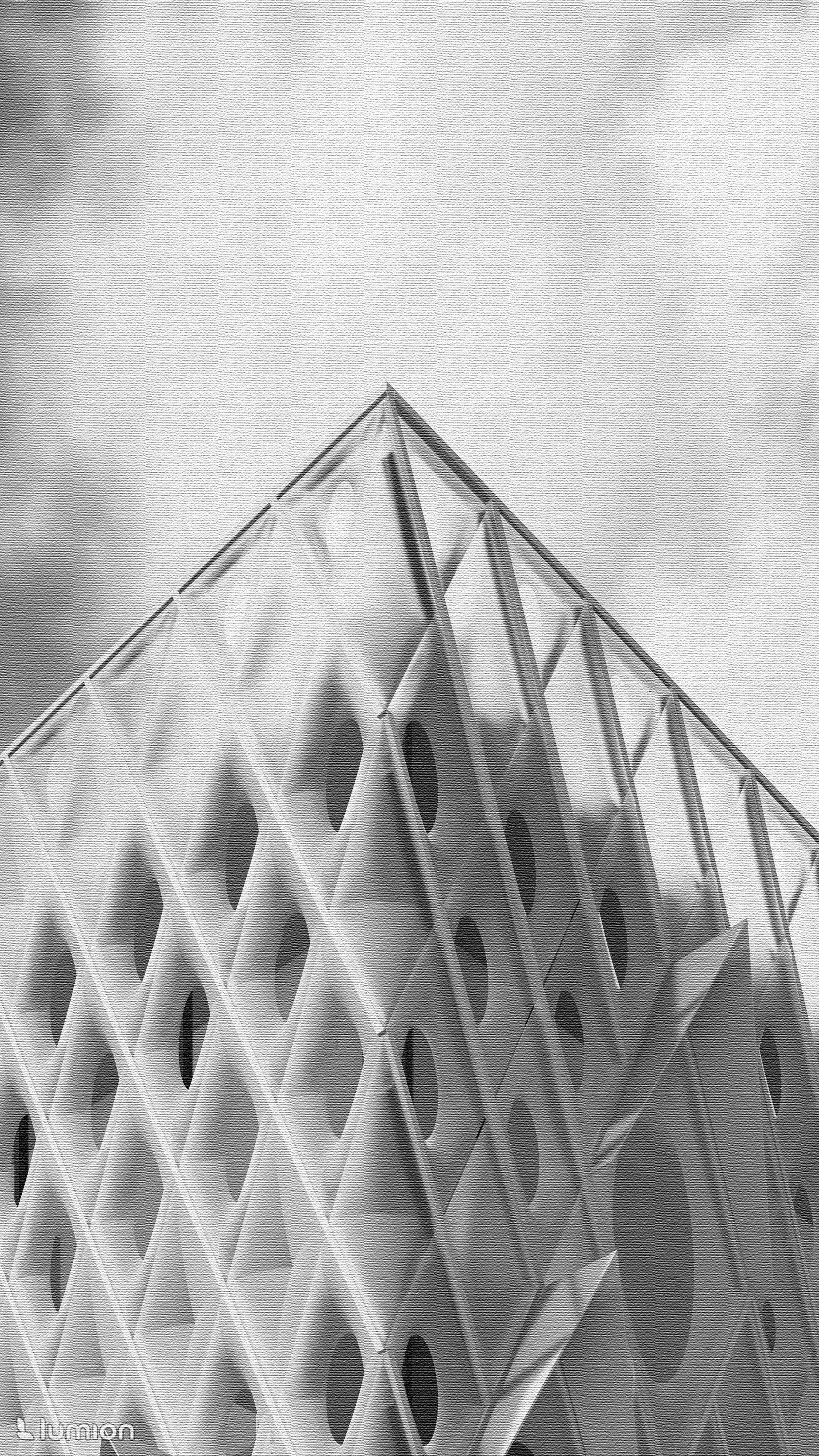

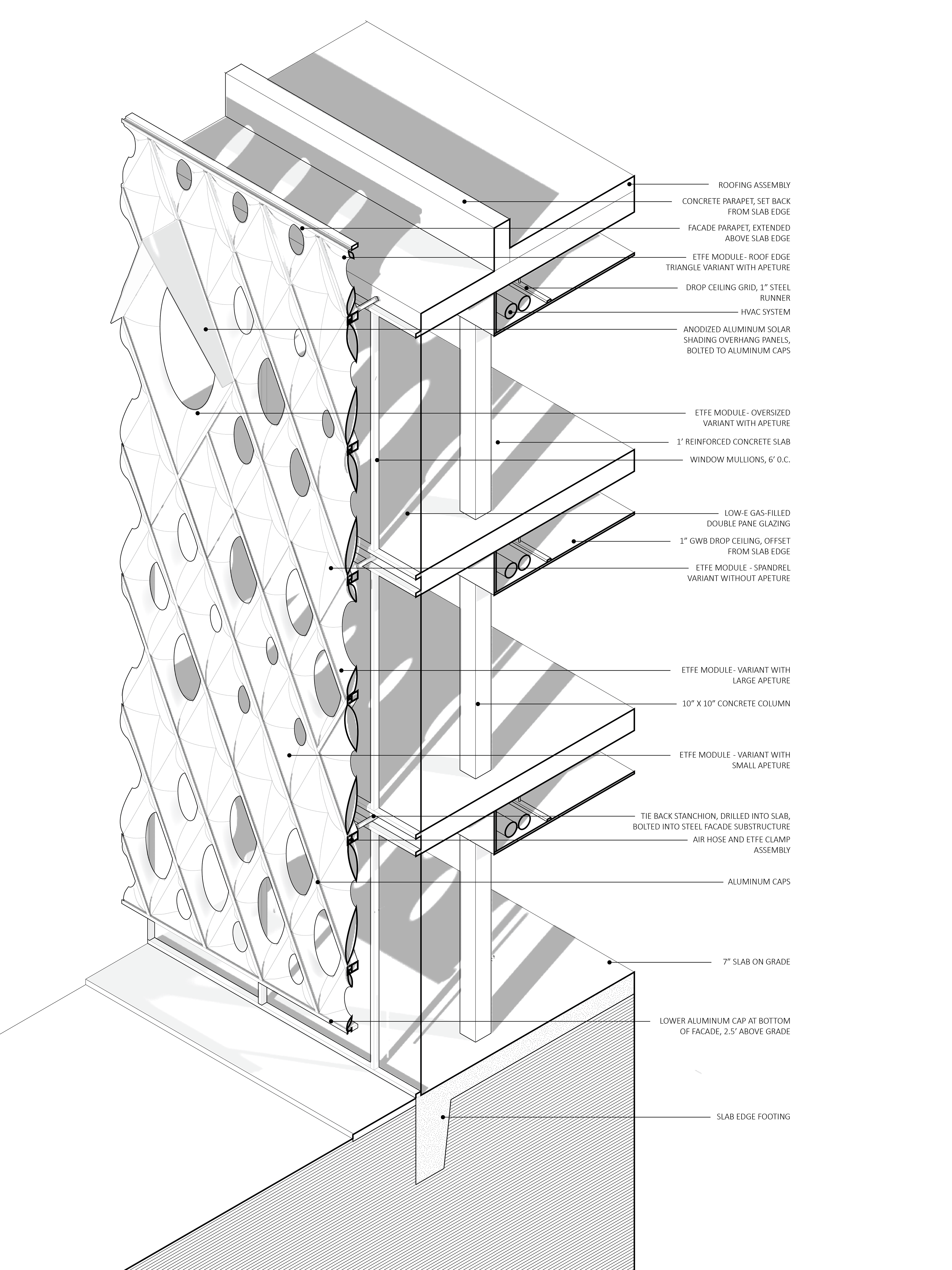

Façade design project exploring the use of ETFE as façade modules. Each pillow, constructed as an inflatable tube, is inflated and clamped onto a diagonal steel substructure offset from the curtain wall. The façade hovers above grade at the ground plane and rises into a parapet, enhancing the feeling of the lightness of the ETFE.

ETFE Modules

Using the cells and pores of tree bark as a generating concept, a set of diamond panels with an aperture inside formed the kit of parts for the façade design. Through digital and physical prototyping techniques, the two scales of modules and material of the pieces were decided, and the connection details between façade and structure were resolved.

Below Left: Detail, Facade Connection at Edge of Slab

Below Right: Detail, Facade Connection at Parapet and Shading Fin

Below Right: Detail, Facade Connection at Parapet and Shading Fin

Light Modulation

The dimensions of the modules, the size of the aperture, and their placement on the elevation were calibrated to respond to the existing mullions that are 6' O.C. as well as the vision zone of the façade. Loosely following a ruleset where modules with no apertures were used to hide the floor plates, while modules with large apertures were placed at eye level, and modules with small apertures were placed near the upper and lower extremities of each floor, the façade aims to achieve an effect of flowing transparencies. Oversized modules running the entire height of the floor were placed as accent pieces that highlight specific programs that would occupy the building behind it.

Below Left: Eye-level perspective showing street corner

Below Right: Wall Section

Below Right: Wall Section

Physical Prototyping

Physical models used to study the façade and module panels.